Wilson & Girgenti – Austin, TX | 3/2024 – 11/2024

Bowman Consulting – KTA – Herndon, VA | 4/2022 – 6/2023

Engineered Composite Systems – Environmental Solutions – Belton, TX | 8/2018 – 1/2022

Atec, Inc. – Houston, TX | 8/2017 - 12/2017

| Certification | Details | Date |

|---|---|---|

| Certified SolidWorks Professional - Advanced Skillset | Advanced Drawing Tools, Weldment Design, Sheet Metal Design, Mold Design | 6/2021 |

| Certified SolidWorks Professional (CSWP) | Mechanical Design | 5/2021 |

| Certified SolidWorks Associate (CSWA) | Mechanical Design | 1/2018 |

| Fundamentals of Engineering (FE) | Mechanical Engineering | 11/2016 |

Click images to view full-resolution CAD models

|

Start Presentation

Watch Nash deliver an interactive walkthrough of an assembly he designed in SolidWorks to tackle a unique design challenge. |

||

| Project Preview | Description | Tools Used |

|---|---|---|

|

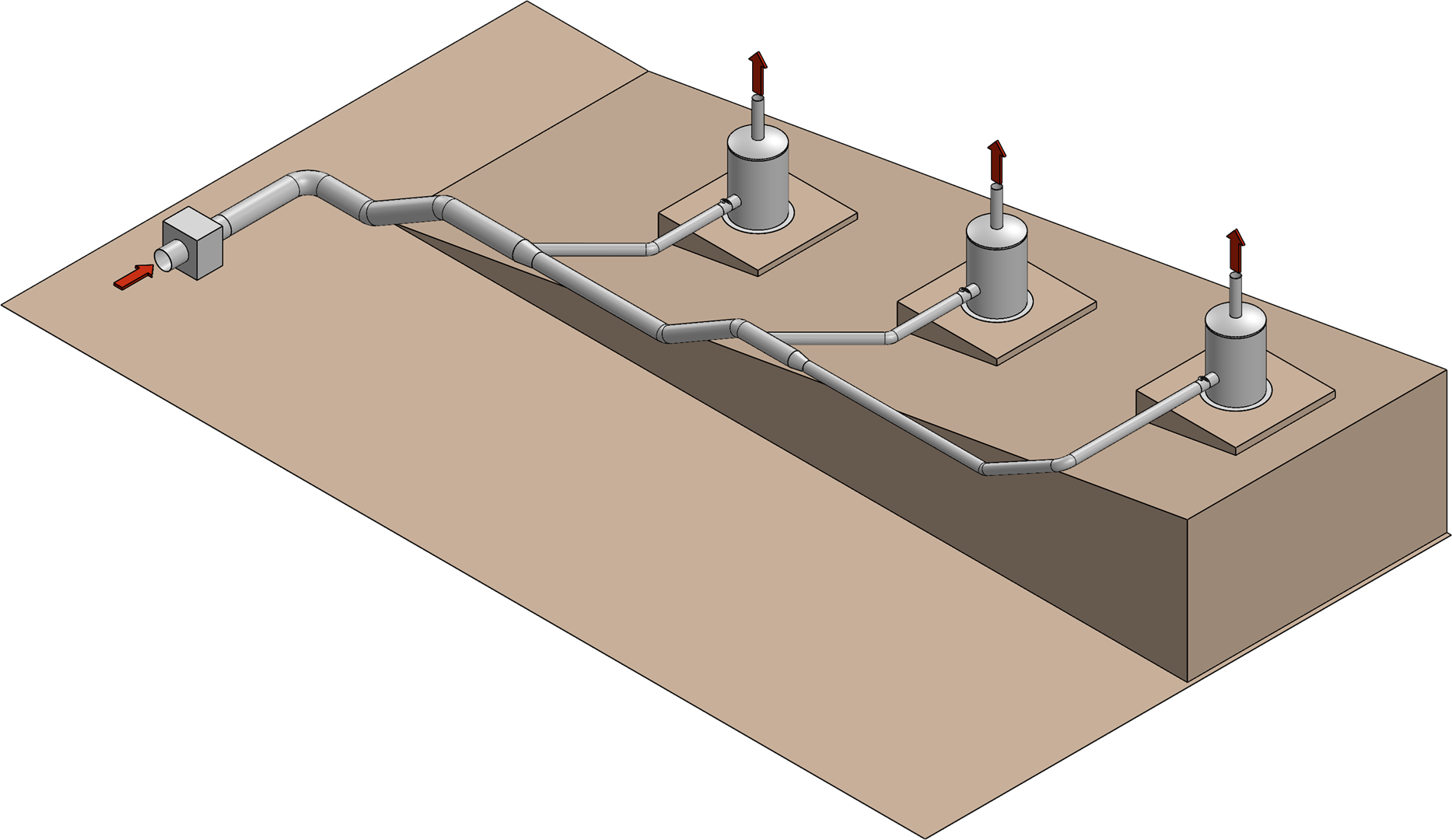

Industrial Scale Air Purification System Optimized airflow design for industrial applications with 40% energy reduction |

SolidWorks |

|

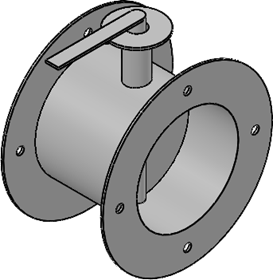

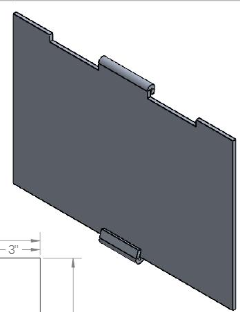

Detailed Component Drawing 3D modeling for damper with precision tolerances |

SolidWorks |

|

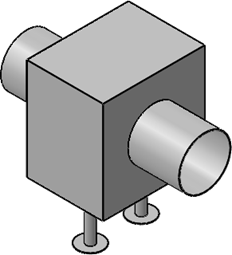

Pre-filter Component Pre-filter component drawing with integration |

SoldWorks |

|

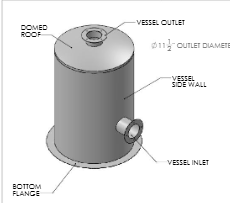

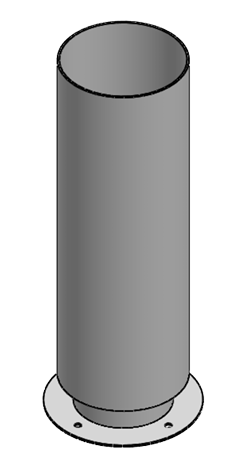

Air Purification Scrubber Vessel Component Air Purification Scrubber Vessel Component Drawing |

SolidWorks |

|

Exhaust Stack Component Exhaust Stack Component Drawing |

SolidWorks |

|

Start Presentation

Watch Nash Nash showcases the full assembly and its moving parts. |

||

|

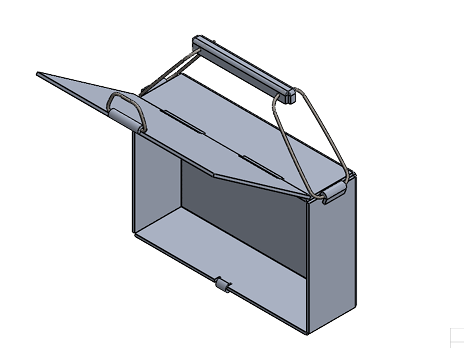

Sheet Metal Design Sheet Metal Lunch Box Assembly Design Project |

SolidWorks |

|

Start Presentation

Watch Nash as he demonstrates how he uses the SolidWorks Sheet Metal Application to create the handle for an aluminum lunchbox. |

||

|

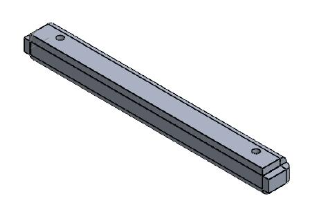

Sheet Metal Design Sheet Metal Lunch Box Handle Design Project |

SolidWorks |

|

Start Presentation

Watch Nash as he demonstrates how he uses the SolidWorks Sheet Metal Application to create the base component for an aluminum lunchbox. |

||

|

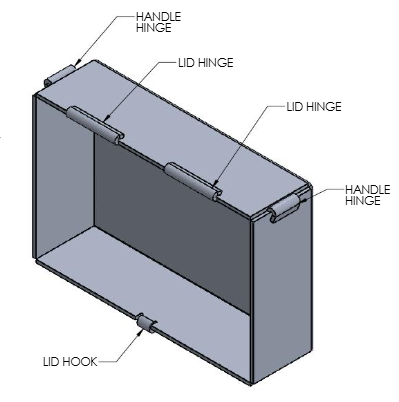

Sheet Metal Design Sheet Metal Lunch Box Base Design Project |

SolidWorks |

|

Start Presentation

Watch Nash as he demonstrates how he uses the SolidWorks Sheet Metal Application to create the lid component for an aluminum lunchbox. |

||

|

Sheet Metal Design Sheet Metal Lunch Box Lid Design Project |

SolidWorks |